Pathways to Reduce Energy Consumption in Lithium-ion Battery Cell Manufacturing

Pathways to Reduce Energy Consumption in Lithium-ion Battery Cell Manufacturing

Executive Summary

Batteries are a key decarbonisation technology as they are required for electrification of transport, storage of renewable energy and for portable electronics. Demand for batteries is expected to grow significantly in response to decarbonisation targets and it is the battery manufacturing industry’s responsibility to reduce embedded carbon in their processes. For the UK and Europe to compete globally in this sector, setting and achieving ambitious sustainability targets is crucial.

For battery cell manufacturing (slurry mixing to formation/ageing), the largest contributor to carbon footprint is energy consumption. Primary data is collected from the process equipment at UKBIC and used alongside cell design parameters to quantify ‘kWhc/kWhp’: the energy consumed (kWhc) to produce 1 kWh of finished cylindrical cells (kWhp).

The main purpose of this study is not the absolute results, which will change depending on product design and factory scale, but identification of the largest contributors to energy consumption in the battery cell manufacturing process, the key factors that influence these, and potential pathways to reduction. The study focuses on cell manufacturing process for defined cell materials and components. Variation in cell materials and components will be excluded to avoid noise in this study.

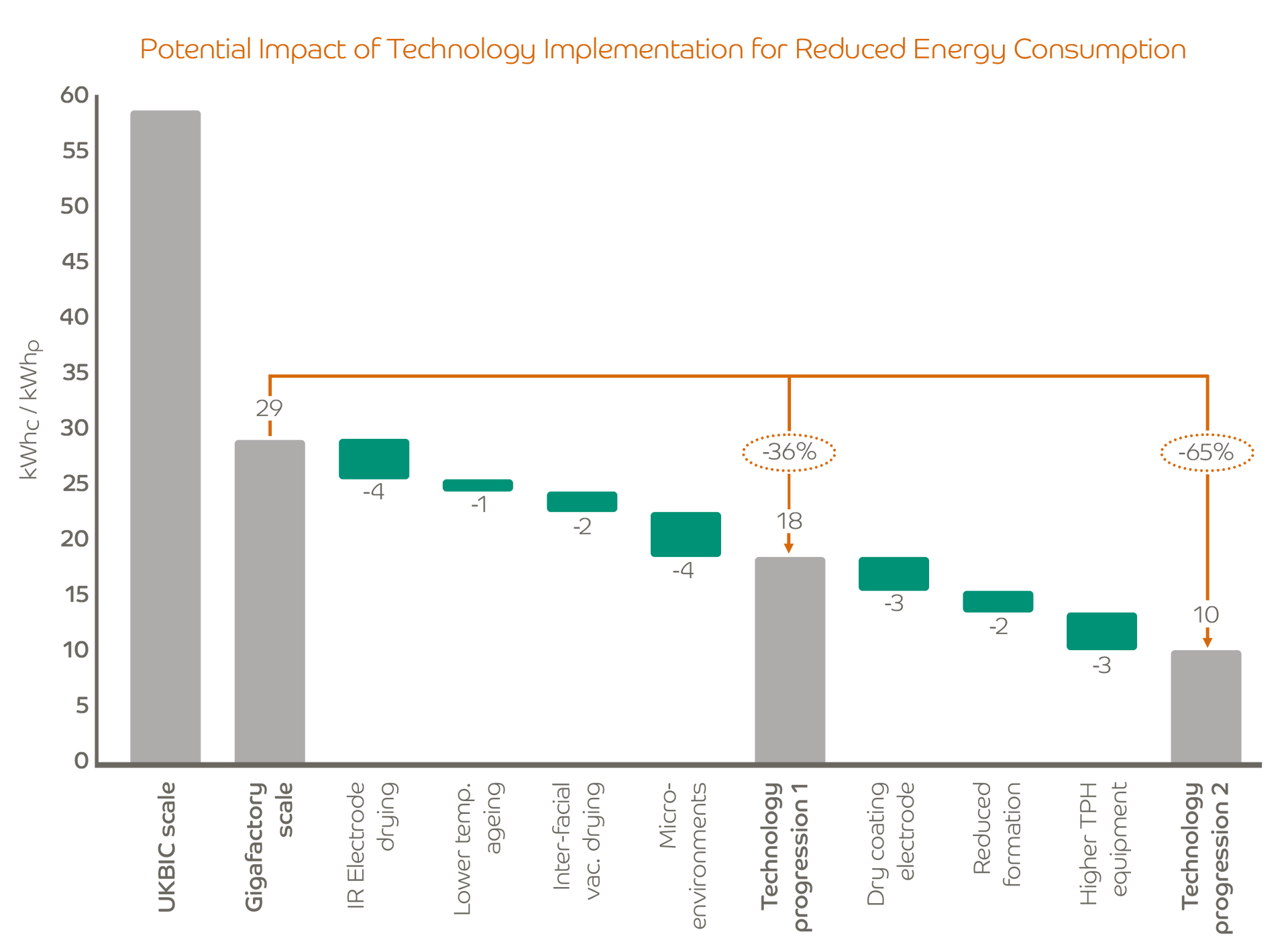

The three largest energy consuming areas are electrode drying, formation & ageing, and the use of dry rooms to create low humidity environments. Deploying technology in these areas could see a reduction of 65% as per Figure 0.1. Reducing energy consumption by 19 kWhc/kWhp could provide an emission savings of 6 MtCO2e per year in 2030 when manufacturing capacity is expected to be 965 GWh/year2 in Europe.

Key Recommendations:

- kWhc/kWhp to be implemented as core KPI in battery cell manufacturing to achieve sustainable cell manufacturing

- Intensive investment in manufacturing research & development and scale up is required to industrialise technologies as soon as possible to reach significant gains towards net zero targets

- High risk technologies need substantial investments, but have the potential to be highly rewarding and will support competitive advantages regarding cost, quality and environmental sustainability in European cell manufacturing